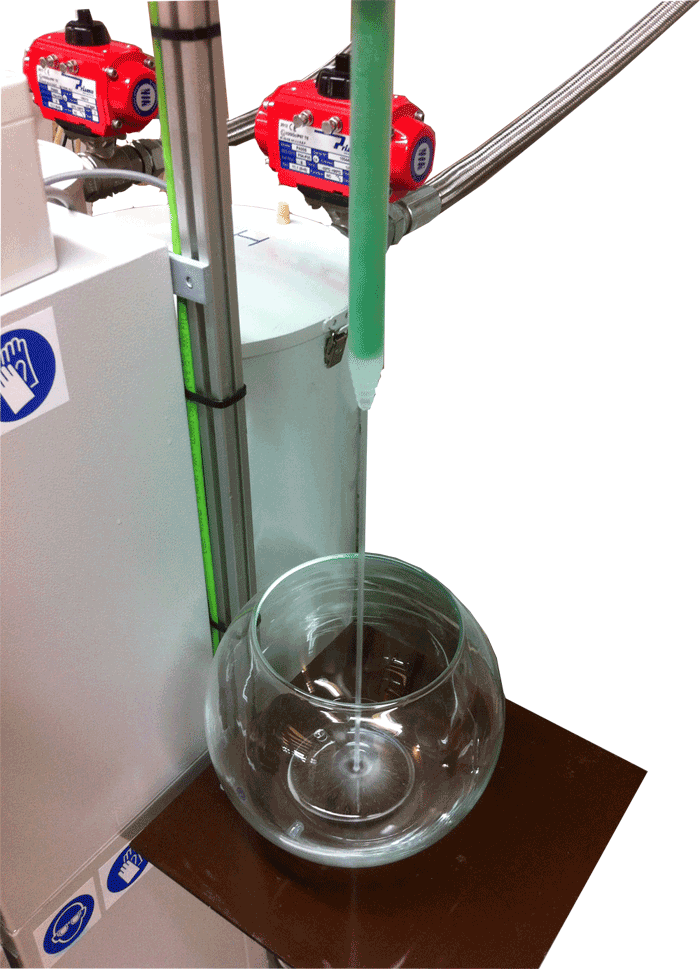

Have you ever wondered how the water in some flower displays doesn’t spill out when the vase is knocked over? Why the water over the pebbles doesn’t move when you disturb the vase? Maybe the answer is that it isn’t water in the first place!Closer inspection reveals a colourless, water clear product which is solid, but retains the look of water in the vase. It is actually water clear epoxy resin.

2KM has recently been contacted to help ensure that the busy production unit at Ruckley Estates, where the world famous Peony Flowers are produced, would be able to maximise their output for the QVC channel sales. Peony flowers are beautifully lifelike and pass even the closest inspection. The attention to detail is excellent and the ‘Resin water’ needed to be equally convincing.

2KM was selected because of the ability to meet Ruckley’s requirements with an understanding of how to improve on existing production methods. Having faced technical and performance issues from the previous machinery supplier, 2KM were a breath of fresh air in responding to Ruckley’s needs.

2KM was selected because of the ability to meet Ruckley’s requirements with an understanding of how to improve on existing production methods. Having faced technical and performance issues from the previous machinery supplier, 2KM were a breath of fresh air in responding to Ruckley’s needs.

Replacing old equipment is never easy, as operators have become used to how the existing equipment functions (including working around the known faults and idiosyncrasies). With this in mind, 2KM set about speaking to the operatives and production team in order to produce a ‘wish list’ for the new machine.

Having taken into account the production requirements and understanding the weaknesses of the old machine, 2KM designed and built a bespoke unit, based on the successful and proven Process Gear Mix 101.

Using gear pump technologies, the PGM101 was designed to deliver a 1:1 volumetric mix at a flow rate of up to 4 Litres per minute, building in plenty of expansion for larger components to be ‘potted’.

From Ruckley’s point of view, it was essential that the PGM101 should be capable of mixing the Water Clear Epoxy Resin, without any swirls or unmixed material visible in the glass vases supporting the Peony flowers. This has proved troublesome in the past, with the mixing arrangement being the most troublesome part of the old machine. 2KM liaised with the material supplier to make sure that the requirements were fully understood and then set about proving the process and exhibit the advantages offered. Using disposable rotary mixers, 2KM installed an efficient unit without the need to introduce solvents. With a long open time on the Epoxy Resin, a single mixer can be used all day, thus reducing waste streams and minimising the maintenance requirements.

2KM also managed to produce a mix which could be dispensed straight into a vase without any secondary mixing process. The mixing arrangement even allowed for previously unattainable products to be filled direct from the mixing station! 2KM met and exceeded expectations!

Noise in the factory was overcome by utilising a servo driven motor which reduced sound output from the mixing, whilst generating a very efficient mix of the Epoxy Resin. Again, 2Km were able to deliver performance above expectations to acclaim from the operatives!

Ease of operation for the operative was also a consideration and again 2KM delivered! Adding timers to the PGM101 allowed for the accurate dispense of materials in known quantities at the press of a single button. This energised the machine dispense pumps and the servo driven mixer simultaneously to produce a quality assured product every time.

The PGM101 unit was also fitted with an automatic filling system for the clean and efficient management of materials via a bulkhead arrangement. Again, this was an improvement on the old machinery and has allowed Ruckley to use the PGM101 as a stand alone unit if required, being easily wheeled to a remote production station before being returned to the bulk filling area. This has allowed Ruckley to consider new production techniques that were unobtainable previously.

The response to the new unit has been immediate, with a unanimous acceptance of the efficiency and ease of use that 2KM had brought to Ruckley’s production facility. You could even go so far as to say, that in this operation, 2KM came up smelling of roses!

For more information on the manufacturer visit the Ruckley website.

You can take a look at the Peony flowers here.