ResinMix RTM Overview

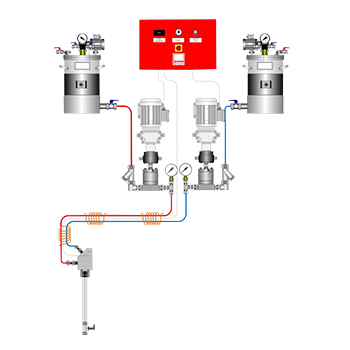

The ResinMix system is adapted to meet different requirements for each market area. For the application using Resin Transfer Moulding (RTM), the unit is further evolved with the system having the ability to control the output dependant on mould pressure.

The system uses special geared Drive motors coupled precision metering pumps to enable the system to hold a material pressure in a mould.

The unit can be equipped with flowmeters to ensure the materials being processed are as specified during the process.

| Metering technology | Individually driven Gear pumps via inverter controlled, geared AC motors |

| Ratio range | 100:100 through to 100:0.5 depending on pump selection |

| Output (depending on Viscosity) | Up to 5,000 cc/min |

| Viscosity range | 200 to 40,000 cps |

| Maximum operating pressures | 100 bar pump pressure 20 bar mould pressure |

| Mixing options | In line static mixer tube |

| Metering control | Yes by gear flowmeters |

| Control systems | PLC control via Bechoff system with 12” |

| Services | 3 phase +N +E 32 amp 8mm air supply 6 bar |

| Options available | Options for servo drive for high pressure RTM Full heating to 90oC Degassing Agitation |

| Area of application | Industry | Process |

|---|---|---|

| Moulding | Aerospace | RTM of air craft interiors |

| Automotive | For the manufacture of lightweight composite elements |

| Typical materials processed: |

|---|

| Epoxy Polyester |