ResinMix DI Overview

ResinMix DI is a further development of the ResinMix range and was developed as a progression from the standard system. The new format has the ability to control the material flow in relation to the pressure in the infusion process. This enables the material to be pumps directly into the mould with the highest flow being achieved when the vacuum is at its lowest.

The output will drop off as the pressure increases preventing deformation of the vacuum bag and voids.

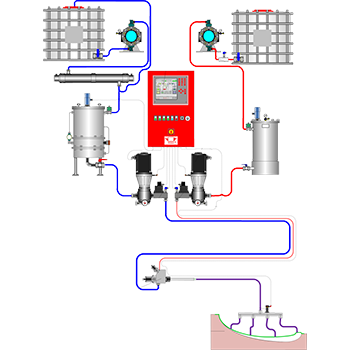

The system is designed to process materials directly from supplied containers with heating and degassing as options.

For totally variable flow the DI is available with geared servo motor drive enabling the system to deliver seamless output from 2 to 60 litres per minute.

| Metering technology | Direct coupling of inverter controlled, geared AC motors directly coupled to variable displacement axial piston pumps |

| Ratio range | 10:100 through 100:100 to 100:10 |

| Output (depending on Viscosity) | Standard ranges are 20, 40 & 65 litres per minute |

| Viscosity range | Up to 2,000 cps (processing viscosity) |

| Maximum operating pressures | 260 bar at pump outlet |

| Mixing options | Disposable static mixers |

| Metering control | By in line gear type flowmeters |

| Control systems | 2KM Microprocessor controller or Siemens s7-300 system. Both with touch screen operator interface |

| Services | 3 phase +N +E 32 or 64 Amp Pneumatic 20mm 6 bar for pump supply |

| Options available | Diaphragm pump supply from IBC or 205 litre drums Supply drum low level Intermediate conditioning vessels In line heating In line degassing Large vessels 2500 litre available |

| Area of application | Industry | Process |

|---|---|---|

| Composites | Wind Energy | Infusion of wind blades |

| Marine | Infusion of Moulds Infusion of large component |

| Typical materials processed: |

|---|

| Epoxy |