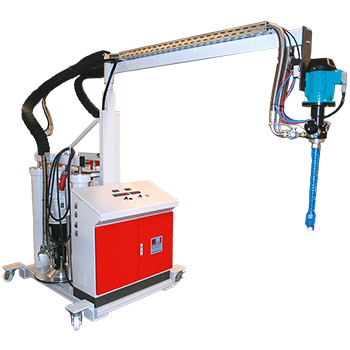

PolyTool 8320 Overview

This system utilises precision, triple screw, progressive cavity metering pumps to apportion low density materials used in the manufacture of marine plugs or automotive models.

The ceramic lined pumps can generate high pressures while handling the filler gently to prevent damage to the spheres during the metering phase of the process.

Each metering pump is directly coupled to an inverter operated, geared AC motor, enabling ratio adjustment suitable to different materials and flow rates.

The standard system is equipped with a disposable dynamic mixer mounted on a swing arm to position the mixed material over the work area.

| Metering technology | Positive displacement screw pumps |

| Ratio range | 50:100 through 100:100 to 100:30 (parts by Vol) |

| Output (depending on Viscosity) | 2 to 8 litres per minute |

| Viscosity range | 100,000 to 500,000 cps |

| Maximum operating pressures | 100 bar |

| Mixing options | High pressure static Rotary static with 4 element disposable mixer |

| Metering control | Not available |

| Control systems | 2KM “easy Use” system with potentiometer adjustment of flow & ratio |

| Services | 16 Amp per phase 3 phase with 6 bar compressed air supply |

| Options available | High capacity ram press Remote mixer head Remote wireless box for start & stop Narrow chassis |

| Area of application | Industry | Process |

|---|---|---|

| Composites | Marine | Manufacture of plugs for moulds Direct tooling for small run part manufacture |

| Wind | Manufacture of plugs | |

| Automotive | Prototype vehicle design |

| Typical materials processed: |

|---|

| Epoxy |