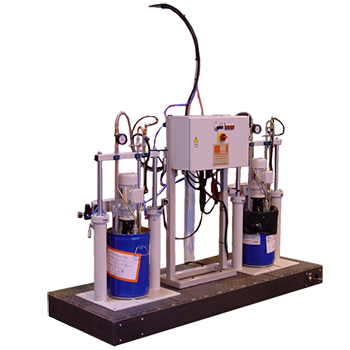

Polymix 100 Overview

The PolyMix 100 system has been developed to dispense medium to high viscosity material directly from the supplied container in a controlled and easily adjustable manner.

The system can be formatted to process differing viscosity media using a common gear pump metering, eliminating the mixing issues associated with reciprocating piston pump systems.

The PolyMix 100 is a variable ratio system and uses inverter drives coupled through an easy to use operator panel.

| Metering technology | Inverter controlled, geared AC motor directly coupled to precision gear pump mounted on follower plates |

| Ratio range | 10 to 100 to 100 to 10 Infinitely variable with like size metering pumps Wider ratio range available upon request |

| Output (depending on Viscosity) | 1 to 4 litres per minute |

| Viscosity range | From 50,000 to 200,000 cps |

| Maximum operating pressures | 100 bar |

| Mixing options | Disposable static mixer to 12mm diameter |

| Metering control | Not available |

| Control systems | Basic operator interface with potentiometers |

| Services | Main drive electrical 240 single phase Compressed air supply for valve operation |

| Options available | Small compact chassis |

| Area of application | Industry | Process |

|---|---|---|

| Composite | Marine | Bonding of fiberglass laminates |

| Bonding | For the bonding of marine hatch lids Glass to metal for shower enclosures |

|

| Casting | Manufacture of moulds for prototyping industries |

| Typical materials processed: |

|---|

| Epoxy Methacrylate Silicone |