PGM Gel Coat Overview

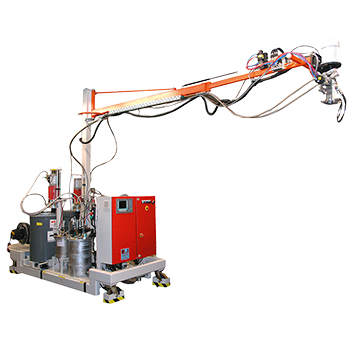

Process Gear Mix system specifically designed for epoxy gel coat systems used in the manufacture of wind blades.

The system is formatted with a chassis that can be towed alongside the blade and the gel coat transferred in to ensure the material has a long open time & work life.

The A component pump is of the hardened type to cope with the abrasive fillers and the B component is the precision, low speed version due to the wide metering ratio and different material viscosities.

The system is monitored by precision flowmeters.

| Metering technology | Individually driven gear pump operated by inverter controlled Geared AC motor |

| Ratio range | 100:100to 100:20 |

| Output (depending on Viscosity) | Up to 9,000 cc/min |

| Viscosity range | Up to 150,000 cps |

| Maximum operating pressures | 2000 bar |

| Mixing options | Swing arm mounted dynamic mixer with speed control and rotational monitor |

| Metering control | Flowmeter option with ratio control & adjustment |

| Control systems | Siemens S7-300 PLC with 8” touch screen monitor |

| Services | 3 phase + neutral + Earth 32 Amp Pneumatics for vessel pressurisation & valve operation |

| Options available | Towed version with cable reels for electrics & pneumatics Compressor mounted on chassis |

| Area of application | Industry | Process |

|---|---|---|

| Composites | Wind Energy | Application of light stable gel coats |

| Typical materials processed: |

|---|

| Epoxy |