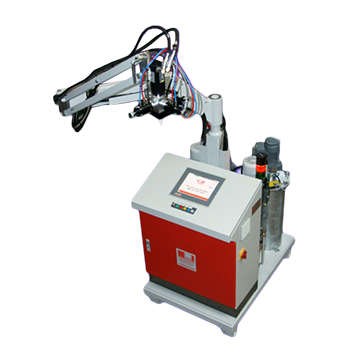

PGM 301 Overview

The Process Gear Mix (PGM) 301 uses the twin drive system found in all PGM machine systems. The 301 version utilises precision gear pumps and a PLC control for machine operation.

The 8.6” touch screen enables the input of application information easily. Up to 10 programmes can be entered and easily recalled from the operating screen.

The application’s parameters, including pressure control, are monitored by the PLC. There are also options for material heating, agitation and vessel refilling.

| Metering technology | Twin Drive Geared AC motors directly coupled to metering pumps |

| Ratio range | 20:100 through 100:100 to 100:20 with like size precision pumps (Other ranges available by changing pump sizes) |

| Output (depending on Viscosity) | Up to 1800 cc/min at 100:100 pbv |

| Viscosity range | Up to 50,000 cps |

| Maximum operating pressures | 80 bar |

| Mixing options | Disposable static Disposable rotary static Hand held dynamic Machine mounted dynamic |

| Metering control | Optional ratio monitoring by flowmeters |

| Control systems | Bechoff PLC with 8.6” touch display |

| Services | 3 phase + N+ E 16 amp |

| Options available | Standard 24 litre vessels option to 90 litre Material heating & agitation Flow meters for ratio monitoring |

| Area of application | Industry | Process |

|---|---|---|

| Moulding | Electrical enclosures | Laying of foam gasket |

| Casting | Prototyping Film props Automotive dunnage Filter production Prosthetic limbs |

|

| Aerospace | RTM process | |

| Laminating | Medical | Coating of substrates Filament winding |

| Coating | Industrial | Spray application of fast reaction PU |

| Bonding | Low viscosity methacrylate materials PU adhesion for filters |

| Typical materials processed: |

|---|

| Epoxy Polyurethane Silicone Epoxy Methacrylate |