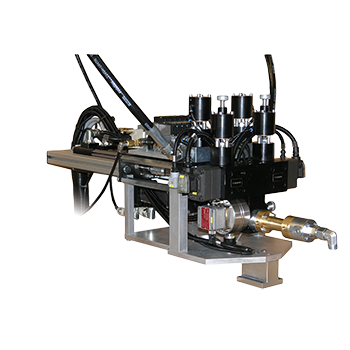

PFM Overview

The Process Flow Mix system (PFM) is based around precision and control of the media being dispensed. The unit utilises shot metering pumps coupled to hydraulic drive cylinders. Pneumatic inlet valves are used to fill the cylinder with outlet valve used to control the pre pressurisation process ensuring the cylinder is correctly charged and ready for the dispense cycle.

Flowmeters can be fitted to confirm the ratio for quality feedback purposes.

| Metering technology | Variable ratio, piston shot metering system |

| Ratio range | 100:100 to 100:20 |

| Output (depending on Viscosity) | Up to 150 ml |

| Viscosity range | 1000 to 1,000,000 cps |

| Maximum operating pressures | 200 bar |

| Mixing options | In line high pressure static mixers |

| Metering control | Yes by flowmeters |

| Control systems | 2KM microprocessor with touch screen Siemens 37-300 PLC |

| Services | 3 phase + Neutral + earth 16 amp 6 bar 10mm pneumatic |

| Options available | Flowmeter feedback 3rd component for pigment of additives Feed from centralised bulk containers |

| Area of application | Industry | Process |

|---|---|---|

| Bonding | Wind | Bonding of root bolts in composite structures |

| Moulding | Silicone | Industrial moulding system with metering at each injection mould machine |

| Typical materials processed: |

|---|

| Epoxy Silicone |