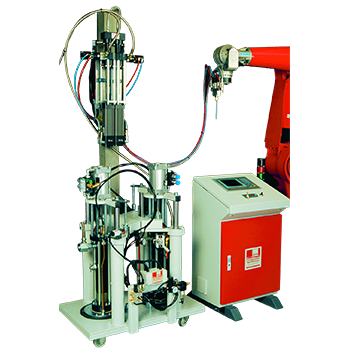

PFM Servo Overview

The PFM Servo (Process Flow Mix) is manufactured to enable multiple metering systems to be used from a single material supply.

The metering is carried out by linear actuators operated by a servo motor drive. The use of servo motors enables the systems to hold against pressure making the unit ideal for 2KM’s “Pre-Press” technology which ensures the metering cylinders are loaded with void free materials.

The pre-pressurisation also ensures the materials are at the correct application conditions when the dispense cycle commences.

Typical applications are the precision dispensing of adhesives and the metering of silicones in a multi machine environment.

All systems have point of application control, with cylinder positional feedback giving accurate application information to the data collection systems.

| Metering technology | Servo driven linear actuator on shot piston metering pumps |

| Ratio range | 10:100 through 100:100 to 100:10 |

| Output (depending on Viscosity) | Max shot 120 ml |

| Viscosity range | 250 to 300,000 cps |

| Maximum operating pressures | 250 bar |

| Mixing options | In line high pressure static |

| Metering control | Feedback from linear transducers on servo drive |

| Control systems | Siemens S7-300 PLC |

| Services | Single phase 240 v electric with pneumatic supply for valve operation |

| Options available | 3rd component Material supply form 20 or 205 litre drums Auto changeover supply system |

| Area of application | Industry | Process |

|---|---|---|

| Composites | Wind Energy | Bonding of root bolts |

| Bonding | Solar | Bonding of 1 & 2 K adhesives for solar panel production |

| Moulding | Liquid Silicone Rubber | Moulding of medical devices and infant feeding systems |

| Typical materials processed: |

|---|

| Epoxy Silicone |