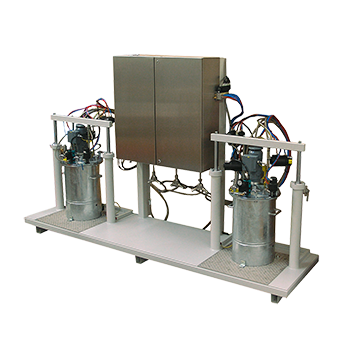

PCM Laminat LH Overview

To process solvent based laminating adhesive directly from the supplied containers, 2KM developed the Process Control Mix (PCM) LH.

This system utilises a batch metering system based around precision flowmeters. This format allows the operator to enter up to 50 recipes into the control system and recall them at the touch of a button. This coupled with the variable volume programme enables batch sizes to be tailored to the job being ran on the laminating system.

The materials are fed to the mixing stations via air operated transfer pumps drawing materials from 1000 litre IBC or 205 litre drums. These materials enter the mixing vessel via pneumatic inlet valves and the materials passing through flowmeters.

| Metering technology | Batch metering with flowmeters |

| Ratio range | 100:1:10 to 100:100:100 |

| Output (depending on Viscosity) | Up to 7 kg/min |

| Viscosity range | 200 to 10,000 cps |

| Maximum operating pressures | 100 bar |

| Mixing options | Mix vessel mounted agitators |

| Metering control | By gear flowmeters |

| Control systems | 2KM Microprocessor or PLC with touch screen interface |

| Services | 240 volt single phase 6 bar 13mm pneumatic supply |

| Options available | High flow transfer pumps for 12 kg/min Interface with existing solvent supply Data logging |

| Area of application | Industry | Process |

|---|---|---|

| Laminating | Packaging | Bonding of foils and printed media for the food & medical packaging industries |

| Typical materials processed: |

|---|

| Polyurethane based laminating adhesives |