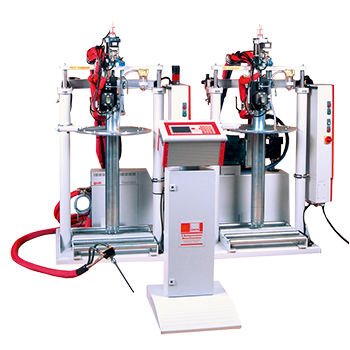

PCM Laminat LF Overview

The Process Control Mix LF is the unit specifically designed to process high viscosity laminating adhesives directly from the supplied containers. The system is based around heated metering pumps immersed, through sealed lids, into the materials to be processed.

The motive power is directly in line with the metering pump and this is provided by servo controlled pneumatic cylinders.

The speed and hence the output from each pump is monitored by flowmeters at the outlet and the reciprocating speed adjusted to meet the entered parameters.

| Metering technology | Servo Pneumatic |

| Ratio range | 10:100 through 100:100 to 100:10 |

| Output (depending on Viscosity) | Up to 2 litres per minute |

| Viscosity range | 3,000 to 90,000 cps |

| Maximum operating pressures | 120 bar |

| Mixing options | Disposable static mixing |

| Metering control | Yes by gear type flowmeters |

| Control systems | 2KM microprocessor with touch screen |

| Services | 240 volt single phase + 6 bar 13mm pneumatic supply |

| Options available | Drum heating Additional metering stations Transfer from IBC |

| Area of application | Industry | Process |

|---|---|---|

| Laminating | Packaging | Laminating of foils for food and medical industry |

| Typical materials processed: |

|---|

| Polyurethane based laminating adhesives |