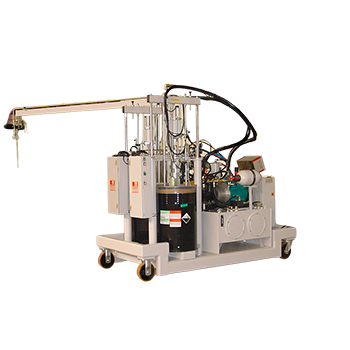

PowerSpray 4060 Overview

Adapted from the high pressure spray systems the 4060 version was manufactured for the processing of high viscosity adhesives directly from the supplied containers.

The metering is carried out by shot metering pumps which are fed by hydraulically operated chop check pumps fitted to follower plates. The nature of the system enables high viscosity products to be metered at high pressure and pumped over long distances.

2 sets of metering pumps are coupled to give a constant material flow.

| Metering technology | Hydraulically driven, single acting shot pumps |

| Ratio range | Fixed 100:100, 100:50, 100:45 & 100:40 (Others available upon request) |

| Output (depending on Viscosity) | Up to 12 kg/min |

| Viscosity range | 250,000 to 1,000,000 cps |

| Maximum operating pressures | Up to 400 bar |

| Mixing options | In line high pressure static |

| Metering control | Ratio monitoring option |

| Control systems | 2KM microprocessor based system |

| Services | 64 Amp 3 phase power with compressed air for valve operation |

| Options available | Heated follower plates Variable ratio (4700 series) Follower plate for low viscosity B |

| Area of application | Industry | Process |

|---|---|---|

| Composites | Wind Energy | Application of reinforced or filled adhesives |

| Coating | Marine | For the spraying of ships hulls |

| Spraying |

| Typical materials processed: |

|---|

| Epoxy Polyurethane |